Professional Document Scanners Verified for Mixed-Media Workflows

For professionals in regulated environments (where a single missing index field can trigger compliance failures), a professional document scanner must transcend speed metrics to deliver verifiable, controlled digital capture. The right professional document scanner establishes reliability as an operational control, not merely a throughput target. When evaluating dual-purpose scanning solutions for environments processing everything from wrinkled receipts to legal briefs, the critical question isn't "How fast can it scan?" but "How reliably does it transform mixed stacks into audit-ready digital assets?" This analysis examines scanning technology through the lens of workflow integrity, where resilience must be designed, not hoped for.

Why Standard Office Scanners Fail in Regulated Mixed-Media Workflows

General-purpose scanners lack the engineered controls necessary for environments where paper represents risk exposure. Most consumer-grade devices treat scanning as a singular event rather than a controlled workflow component. When processing stacks containing business cards, passports, creased receipts, and duplex legal documents, these devices typically exhibit:

- Media handling fragility: Unmanaged feed paths that can't adjust to document thickness variations

- Silent data loss: Auto-crop failures that trim critical index fields without notification

- Incomplete audit trails: No immutable record of document sequence or exception handling

During a healthcare compliance rehearsal I supported, a "smart" scanner failed catastrophically when encountering patient wristband labels, losing critical MRN index fields with no recovery path. This incident revealed how consumer-oriented error handling protocols treat exceptions as user problems rather than system design flaws. Document the exception path before you deploy any scanner in regulated workflows. For proactive jam prevention and upkeep, see our scanner maintenance guide.

Professional-grade devices address these gaps through:

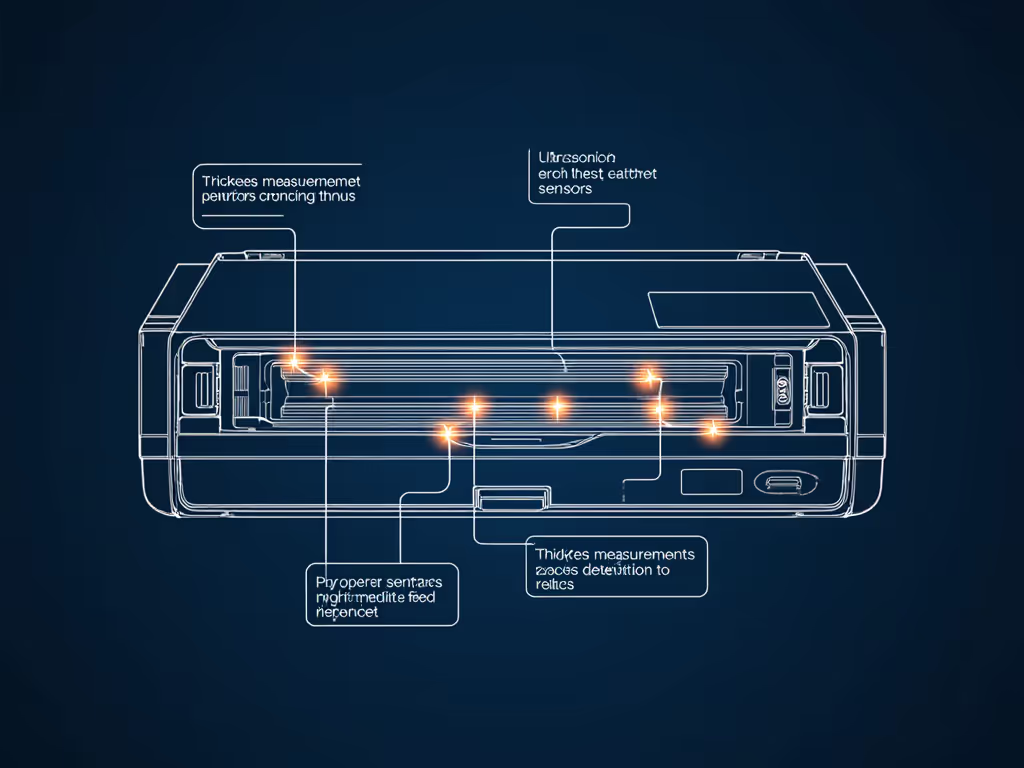

- Precision media sensors that measure document thickness (e.g., Canon DR-C225 II's ultrasonic double-feed detection)

- Verifiable exception logging showing exactly which pages triggered interventions

- Controlled batch sequencing that maintains document order even during jams

What Makes a Scanner Truly 'Regulation-Ready'?

Certified compliance isn't about checklists, it is about engineered workflow controls. A regulation-ready professional document scanner must provide:

Verifiable Capture Integrity

Every scanned document must maintain chain-of-custody evidence through:

- Immutable timestamping: Embedded in PDF/A metadata showing exact capture time

- Document sequence logging: Digital record of original stack order

- Error code standardization: Specific codes for each exception type (e.g., "ADF-07: curvature beyond tolerance")

The Xerox Duplex Combo exemplifies this through its integrated Visioneer Acuity software, which generates machine-readable logs showing not just that a scan occurred, but the precise conditions under which it succeeded or required intervention. This transforms scanning from a black box into a controlled workflow component.

Controlled Media Adaptability

True mixed-media scanning capability requires more than physical accommodation, it demands systematic adaptation:

| Control Measure | Consumer Scanner | Professional Scanner |

|---|---|---|

| Thickness Variation | Manual intervention required | Automatic sensor calibration |

| Skew Tolerance | ±5° before failure | ±15° with correction |

| Sequence Integrity | Lost on jam recovery | Preserved via batch checkpointing |

The Epson DS-320 achieves this through its adaptive separation rollers and real-time curvature sensors, which automatically adjust feed pressure based on document characteristics. This is not convenience, it is a risk control preventing data loss from physical document variations.

How to Verify Scanner Resilience in Real Workflows

Marketing specs rarely predict operational reliability. Validate professional document scanner resilience through:

Stress Testing Protocol

Execute three critical tests before deployment:

- Mixed-stack endurance test: Process 50-page batches containing:

- 10 receipts (varying thickness)

- 5 credit cards

- 15 duplex legal documents

- 5 creased pages

- 10 passport-sized items Measure exception rate and recovery time

-

Continuity validation: Verify sequence preservation after forced jam recovery

-

Log verification: Confirm exception logs contain:

- Timestamp of error

- Document position in batch

- Corrective action taken

- Final disposition status

Document the exception path before deployment. The scanner that never jams is less valuable than the one whose jams never break workflow continuity.

Integration Verification Framework

Regulated workflows demand more than PDF creation, they require controlled data routing. Validate integrations by:

- Testing direct-to-SharePoint uploads with metadata injection

- Confirming TLS 1.2+ encryption during transmission

- Verifying error logs persist when cloud connections fail

- Checking compatibility with your specific DMS security protocols

The Brother ADS-2700W demonstrates this through its dual connectivity (Ethernet/USB) with separate authentication protocols for each channel, ensuring compliant data routing regardless of network conditions. To harden this layer, follow our zero-trust scanner security guide for segmentation, authentication, and data handling patterns.

What Metrics Actually Matter for Mission-Critical Workflows?

Forget pages-per-minute; regulated environments require high-fidelity document capture metrics that reflect operational reality.

True Throughput Calculation

Real-world speed = (Total pages) ÷ (Total processing time including exceptions)

This accounts for:

- Jam recovery time

- Exception handling duration

- Staff reprocessing effort

A scanner rated at 40 ppm but requiring staff intervention every 75 pages may deliver lower true throughput than a 25 ppm device with 99.8% first-pass success rate.

Document Integrity Score

Measure:

- % of pages requiring manual correction

- % of documents with missing metadata

- OCR accuracy on critical fields (not overall text)

This metric directly correlates with audit readiness. In legal workflows I've hardened, a Document Integrity Score below 99.5% triggers immediate workflow review. If you rely on extracted text, compare engines using our OCR software accuracy review.

Critical Implementation Controls for Long-Term Success

Scanner reliability decays without proactive controls. Implement these safeguards:

Predictive Maintenance Protocol

- Track roller wear via page count thresholds

- Schedule calibration after each 10,000-page milestone

- Monitor ultrasonic sensor drift through test pattern scans

The Plustek OS 1180's self-diagnostics suite exemplifies this approach, providing advance warnings when media handling tolerance approaches critical thresholds, allowing intervention before failures occur. For long-term purchase decisions, consult our verified scanner durability data based on failure rates and service reports.

Staff Handoff Standardization

Create explicit protocols for:

- Exception handling responsibilities

- Batch reconciliation procedures

- Media-specific scanning profiles

Document the exception path before staff turnover creates knowledge gaps. Standardized workflows transformed one healthcare client's audit outcomes from consistent exceptions to zero findings within six months.

Choosing Between Specialized and Dual-Purpose Solutions

For organizations handling both standard documents and specialty media (ID cards, passports, long receipts), dual-purpose scanning solutions require careful evaluation:

When to Choose Dedicated Devices

Opt for specialized scanners when:

-

30% of workflow involves non-standard media

- Regulatory requirements mandate specific validation protocols

- Throughput requirements exceed 1,000 pages/day

When Dual-Purpose Solutions Excel

The Canon DR-C225 II demonstrates effective dual-purpose design through:

- Automatic media thickness detection (23-413 gsm)

- Long-document support up to 120"

- Integrated color dropout for official stamps

This provides creative workflow optimization without compromising regulatory controls, critical for accounting firms handling both tax forms and client identification.

Conclusion: Scanning as a Control Function

In regulated environments, a professional document scanner isn't an office appliance, it is a control point in your compliance architecture. Reliability is a control, not a nice-to-have in regulated workflows. The scanners that deliver lasting value don't just move paper to digital; they embed verifiable integrity at every transition point.

When evaluating options, prioritize engineered resilience over speed claims. Verify true exception handling capabilities through structured testing. Demand immutable audit trails that survive regulatory scrutiny. The investment in properly controlled mixed-media scanning pays exponential returns when the next audit cycle arrives.

Further Exploration

For those responsible for workflow integrity in regulated settings, deepen your understanding through:

- NIST SP 800-88 media sanitization guidelines

- AIIM's standards for digital capture in legal workflows

- ISO 32000-2 (PDF 2.0) specifications for archival formats

- Vendor-agnostic scanner validation checklists from compliance-focused industry groups

Document the exception path before your next scanner evaluation begins, your audit trail depends on it.